Superabrasives (classified by industry)

Integrity based, innovation driven

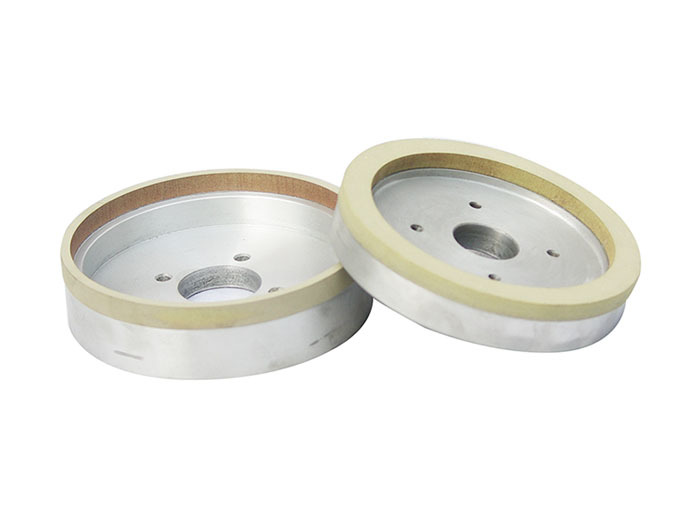

Grinding PCD saw blade, ceramic diamond grinding wheel

Advantages of PCD saw blade ceramic diamond grinding wheel products: Our company specializes in prod

Category:

Contact us

Product description

Our company specializes in producing ceramic bonded diamond grinding wheels for PCD cutting tools, mainly used for grinding the front, back, and side edges of circular saw blades, band saws, and other materials such as hard alloys, high-speed steel, metal ceramics, PCD, etc. The product has excellent performance and low price. Welcome friends in the industry to choose.

Product superiority (compared to resin diamond grinding wheels)

1. High durability and good shape retention: Its durability is 2-3 times that of resin grinding wheels under the same grinding conditions. The grinding wheel has strong abrasive bonding force, uniform and stable wear, and the shape of the grinding wheel is not easily changed;

2. Good sharpness: Its grinding efficiency is about twice that of resin grinding wheels;

3. Good adjustability: It has the same adjustability as ordinary ceramic corundum and silicon carbide grinding wheels;

4. The production of grinding wheels with a particle size of 0-5 μ m for ultra precision grinding has superiority, which is the bottleneck of resin grinding wheels;

5. The comprehensive cost of grinding can be reduced by 20% -30% compared to resin grinding wheels.

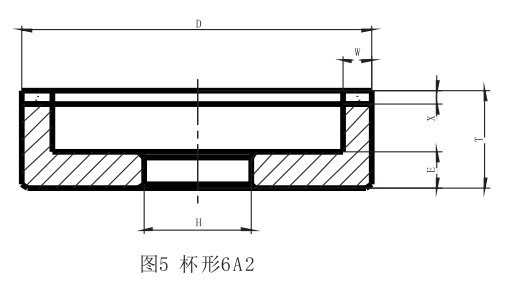

Ceramic diamond grinding wheel specifications:

6A2 150 × 38 × 40 (or 32 inner holes) × 5 × 10 fine gauge

6A2 150 × 38 × 40 (or 32 inner holes) × 5 × 11 fine gauge

6A2 150 × 38 × 40 (or 32 inner holes) × 5 × 12 fine gauge

6A2 150 * 30 * 32 * 15 * 10 bold size

(In addition to the above specifications, it can also be processed according to customer requirements)

Related products